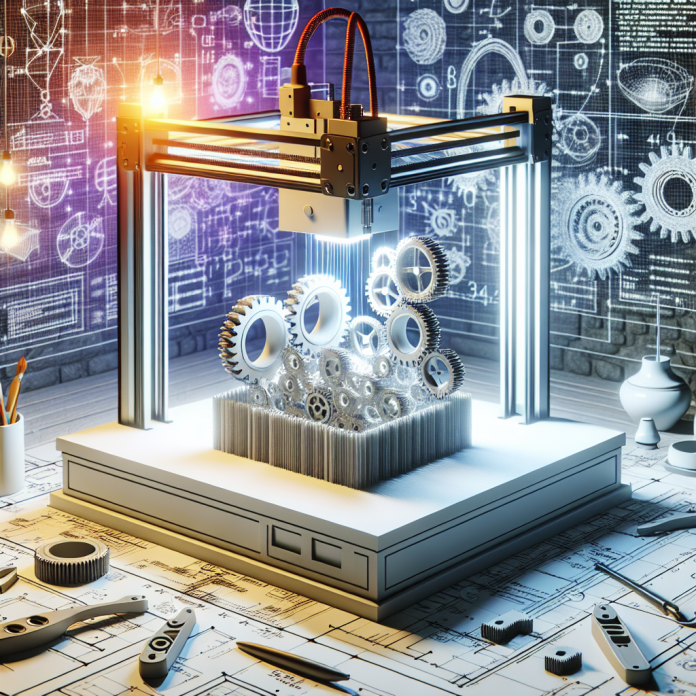

3D printing, also known as additive manufacturing, is a revolutionary technology that is changing the way products are designed and produced. Instead of traditional manufacturing methods that involve cutting, molding, and assembling materials, 3D printing builds objects layer by layer using a digital file as a blueprint.

One of the key advantages of 3D printing is its ability to create complex shapes and structures that would be difficult or impossible to produce with traditional manufacturing techniques. This opens up new possibilities in industries such as aerospace, healthcare, and automotive, where customized and lightweight parts are in high demand.

With 3D printing, designers can quickly iterate on their designs, making it easier to test and refine prototypes before moving into full-scale production. This results in faster time-to-market and lower costs compared to traditional manufacturing methods.

Another benefit of 3D printing is its sustainability. Traditional manufacturing processes often result in a significant amount of waste, as materials are cut and shaped to create products. 3D printing, on the other hand, is an additive process, meaning that only the necessary amount of material is used to create an object, reducing waste and minimizing environmental impact.

As 3D printing technology continues to advance, the possibilities are endless. From printing organs for medical transplants to creating custom-designed furniture, the future of manufacturing is truly being shaped one layer at a time.

Whether you’re a designer, engineer, or entrepreneur, embracing 3D printing can open up new opportunities for innovation and creativity. With its ability to produce customized, complex, and sustainable products, 3D printing is truly revolutionizing the way we manufacture goods in the 21st century.